|

LW卧式螺旋卸料沉降离心机

收藏

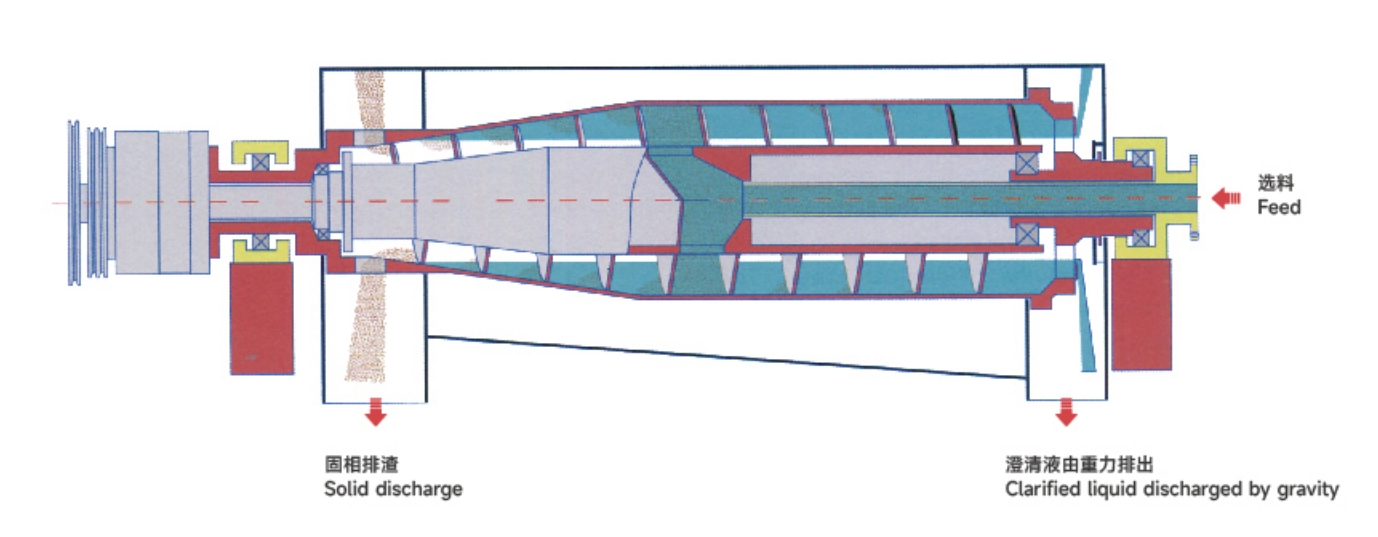

悬浮液从进料管经布料体分配进入转鼓,较大比重的固相颗粒在离心力场的作用下,加速沉降至转鼓壁上。沉降的固相在螺旋输送器叶片的推动下,从沉降区(圆柱转鼓)通过干燥区(圆锥转鼓)至固相出口排出;澄清后的液相从大端溢流口排出。从而实现固-液二相或固-液-液三相分离。 Separation takes place in a horzontal bowl equipped with ascroll convey or The process material is fed into the bowl through a stationary inlet tube and is smoothly accelerated in the accelerate chamber Centrifugal forces cause instant sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl but at a different speed thus moving the solids towards the conical end of the bowl. 主要性能 Performance: LW系列卧式螺旋卸料离心机为卧式,连续进料螺旋连续卸料的沉降心机,主要适用于化工、医药、环保、矿山、食品等行业悬浮液的固-液二相、固-液-液三相分离。 应用领域 Applications: 工业废水和城市污水分离 淀粉洗涤分离脱水 抗生素发酵液菌丝体分离 大豆小麦类蛋白的脱水 鱼粉鱼肉的脱水酒糟脱水 果汁的净化与果肉纤维的脱水 动、植物油的分离与净化 煤焦油的分离与净化 高岭土、石墨的粒度分级染料、颜料的分级与脱水 浮选精煤与煤泥脱水 选矿矿浆的分级与脱水钻井污泥处理 Industrial and municipal wastewater treatment Oil & gas drilling mud/fluid control Washing, classification and dewatering of amylum and starch Mycelium separation from zymotic fluid of antibiotic Dewatering of soybean and wheat protein Dewatering ol fish power and tish meet Dewatering of grains Clarification and extraction of fruit juiceClarification and pu rification for animal and vegetable oil Production and extraction of olive oil, palm oil, avocado oil Separation and purification for coal tar Grading of kaolin and graphite Classification and dewatering for dyestuff and pigment Float wash of extractive coal and dewatering of coal mud Classification and dewatering for minerals 主要特点 Main features 立式机座设计,电机与转鼓对称布局机器运行平稳,振动烈度低 转鼓、螺旋等主要零部件采用离心铸造耐蚀不锈钢或双相钢制造,极限转速高,分离因数大。双电机控制,转鼓、螺旋转速分别无级可调。 螺旋输送器推料表面喷涂耐磨合金或镀焊硬质合金。 摆线齿轮行星齿轮和液压差速器三种结构选择,差速调节范围大,用于不同固相的推料扭矩传递 多重安全保护:转速、差速检测,过振动保护,电机过载过热保护,轴承温度监控,螺旋推料扭矩保护、密闭防爆氮气保护等。 JG型专用橡胶减振器,无需地脚螺栓固定。 Vertical base design and symmetrical arrangement o motor and bowl assembly that ensures stable operation and less vibration Main parts such as the bowl and conveyor are made 0 corrasion-resistant stainless steel or duplex steel, oftering high maximum bowi speed and high centrifugal force. Dual motor drve makes bowl speed and conveyor speed adjustable. Screw conveyor flights tiled or lined with ceramic, tungsten carbide,or other hard alloys Optional planetary gearbox and hydraulic gearboxoffering wde range ot diferental speed aojustment Multiple safety protection bowl speed and differential speed detection overvibration protection motor overload and overheat protection,bearing temperature monitoring , conveyor torque protection and gas tight explosion-proof protection JG type rubber vibration isolator no need of anchor bolts

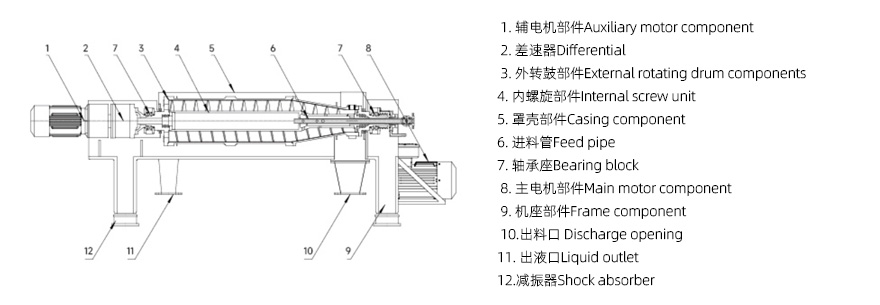

主要结构 Main structure

LW 系列常规机型转鼓两端采用迷宫式密封,分离后固相由螺旋推至固相出口,经高速旋转产生的离心力排出机外; 分离后澄清液经过溢流口,由重力及离心力排出。该机型操作方便,运转连续、平稳,适用范围广。 Labyrinth seal is used for both bowl ends of LW standard typedecanter centrifugesimple and convenient, after separation, the solid phase is conveyed to the solid discharge port by scroll conveyor, and discharged out of centrifuge under centrifugal force caused by high speed rotation: while the liquid phase drains out under gravity and centrifugal force through the overflow plate. This series decanter centrifuge features easily operation continuous and stable running,and wide application scope

技术参数 Technical parameters

|